This unit machine is special design for packaging liquid& sauces product into plastic bag .The machine have the function of automatic bag forming, Liquid product measuring and filling .With optional function of exhausting the air inside the bag and then sealing the bag .The machine also have color ribbon for date printer for coding of expiry date and production date.Widely use for packaging different liquid and paste product.

1, ZL520 vertical bag forming filling sealing Packaging machine

The whole machine made by Stainless Steel 304. This machine equipped with bag-making, cutting, code printing, etc. Siemens PLC and Touch Screen,Panasonic servo motor, Japanese Photo Sensor , Korean Air valve, etc. .The film pulling system adopted servo motor driving making speed faster.

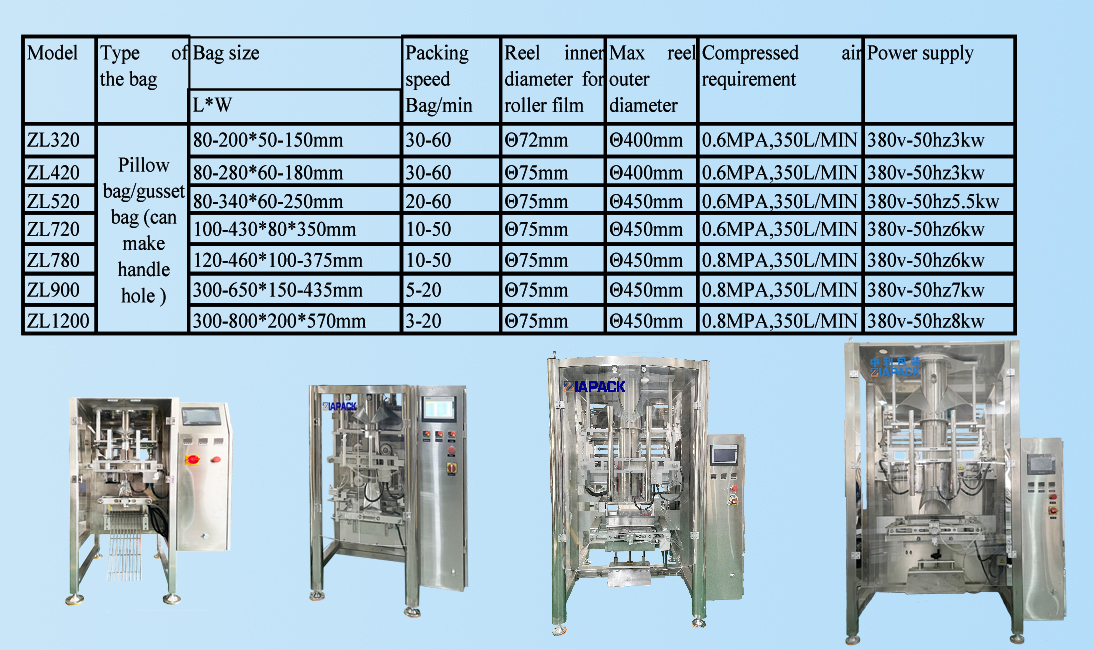

Tehniskie parametri:

Weighing Range: 1000-2000g

Packaging Speed: 20-40 bags/min

Bag size: (80-360)*(100-250) mm (L*W)

Nepieciešamība saspiestajam gaisam: 0,6 Mpa 0,65 m³/min

Reel outer diameter: 400mm

Serdes iekšējais diametrs: 75 mm

Machine weight: 800kg

Power source: 5.5kW 380V±10% 50Hz

Galvenās īpašības un īpašības:

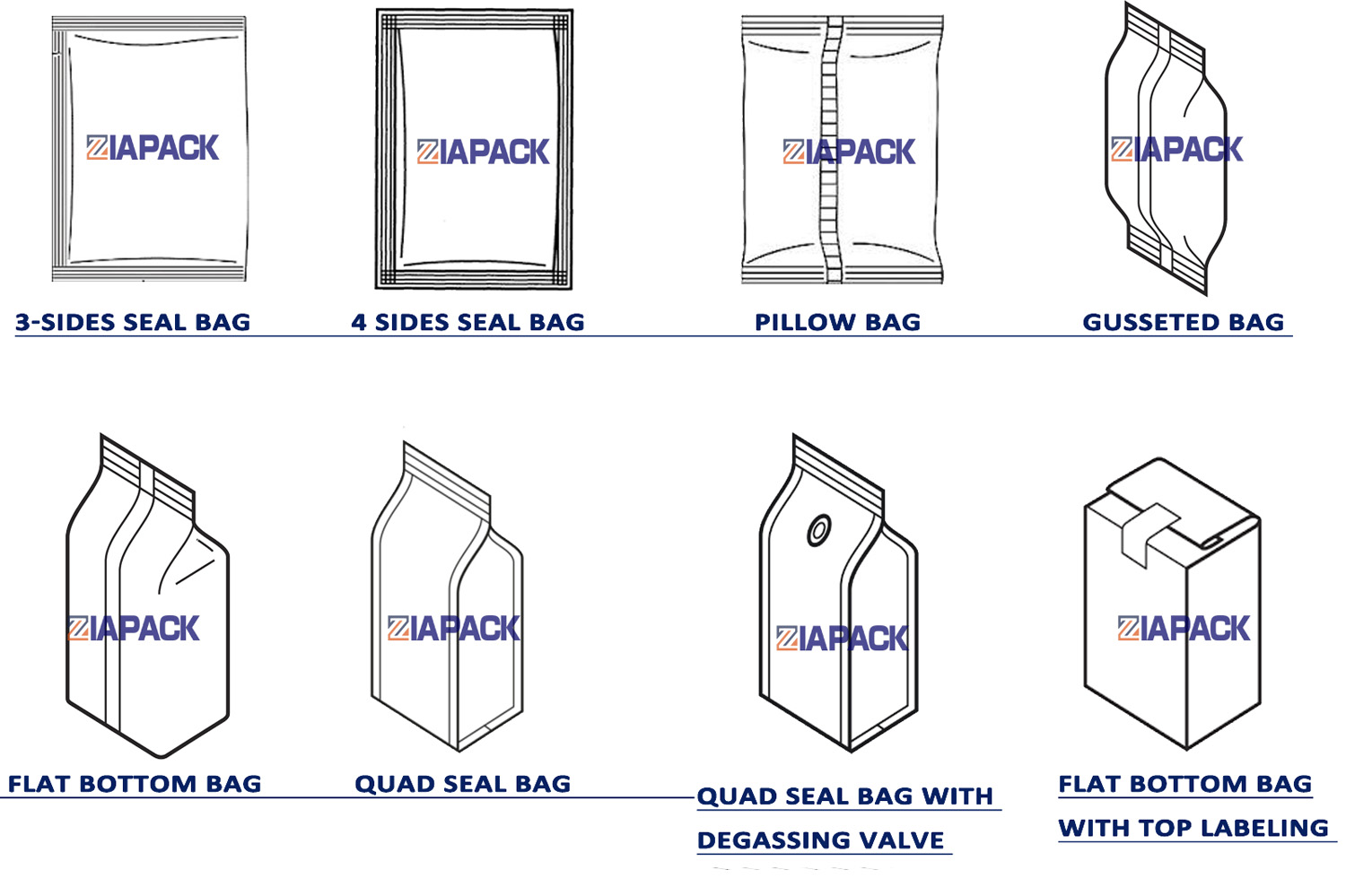

A wide range of pouches: Pillow and Gusset pouches.

High speed: 20-50 bags/min

Viegli lietojams: PLC kontrolieris un krāsains skārienekrāns, skārienekrānā kļūdas indikācija.

Viegli regulējams: tikai aptuveni 10 minūtes, lai mainītu dažādus maisiņus.

Frekvenču kontrole: ātrumu var regulēt ar frekvenču konversiju diapazonā.

Augsta automatizācija: bezpilota svars un iesaiņošanas process, automātiska trauksme automātiski, kad kļūme.

Drošība un higiēna:

Nav filmas, mašīna signalizēs.

Iekārtas signalizācija un apstāšanās, ja nepietiekams gaisa spiediens.

Drošības sargi ar drošības slēdžiem, mašīnas signalizācija un apstāšanās, atverot drošības aizsargus.

Higiēniskā konstrukcija, produktu kontaktu daļas tiek pieņemtas ar nerūsējoša tērauda sūkni.

Bag type

2,ZLB100 Piston pump with hopper

Iespējas

Standard with Airtac Piston.

All piston filler made from S/S 304 grade stainless steel and aluminum conforms to GMP.

Suit for Viscous Liquid Model with stainless steel product hopper

Operated by foot pedal switcher or matching with full automatic packaging machine

With Anti-leaking system

Quick release nozzle and feed pipe

Technical parameter :

Filling range: 50-500 ML

Power supply: 220V 50HZ

Total power Power: 1650W

Heating power:1500W

Temperature range:20-90℃

Weight: 55kg

Hopper capacity: 30L

Air pressure: 0.4-0.6mpa

Working mode: need to be equipped with a power supply and air compressor

Machine material: case 201 stainless steel, material contact part is 304 stainless steel

Pildījuma precizitāte: ± 1%

Filling efficiency: 0-25 bottles /H

Packing size:96*36*36cm (machine) + 60*54*81cm(hopper)